Combo and Dual Vending Machines

Chips, candy, pastries, gum and mints, soda, juices, bottled water and even dairy products can be made available through combo vending machines.

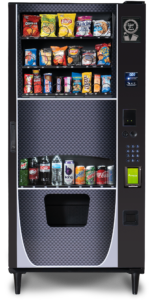

Express Combo Vending Machine

Vending.com’s best-selling Express Combo snack and drink vending machine will satisfy your customers with ease. Plus, the new carbon fiber door graphic styling of the Express Combo machine will make your machine stand out in any location and entice customers to make a purchase. The best part? This combo vending machine will pay for itself with just a few product sales per day!

View NowePay Combo Vending Machine

Easily accommodate ALL major credit cards, debit cards and mobile wallets, including Apple Pay and Google Pay with the NEW ePay Combo Vending Machine. Equipped with the Greenlite Cashless System, the ePay Combo Vending Machine is a cashless electronic payments only machine.

View NowMarketOne 5W Snack and Cold Drink Vending Machine

The MarketOne 5W Snack and Cold Drink Vending Machine gives customers easy access to refrigerated food, snacks and cold beverages, as well as an unparalleled vending experience through a large merchandising window and enhanced LED lighting.

View NowMarketOne 3W Snack and Cold Drink Vending Machine

The MarketOne 3W Snack and Cold Drink Vending Machine give customers easy access to refrigerated food, snacks and cold beverages, as well as an unparalleled vending experience through enhanced, LED lighting.

View NowMarketOne 3W Cold Food and Drink Vending Machine

Your customers will love the top-notch vending equipment you provide with the MarketOne 3W Cold Food and Drink Vending Machines. It is the perfect machine for any high-traffic location, as it offers up to 36 selections of cold food.

View NowMarketOne 5W Cold Food Elevator Vending Machine

The elevator feature on the MarketOne 5W Cold Food Elevator Vending Machine allows you to vend fragile products, such as yogurt and salads, from your vending machine. Additionally, it features a large, LED merchandising window and enhanced LED lighting.

View NowMarketOne 5W Outdoor Vending Machine

The MarketOne 5W Outdoor Vending Machine was built with maximum durability that can withstand the elements. It features rain guards, anti-pry covers and an impact-resistant polycarbonate window cover with a steel frame.

View NowCompact 23/10 Combo Vending Machine

Comprising two machines, the Compact 23/10 Combo Vending Machine is created to hold a variety of snacks and beverages for your customers to enjoy.

View NowMidsize 32/10 Combo Vending Machines

Made up of two vending machines, the Midsize 32/10 Combo Vending Machine holds a variety of snacks and beverages for your customers.

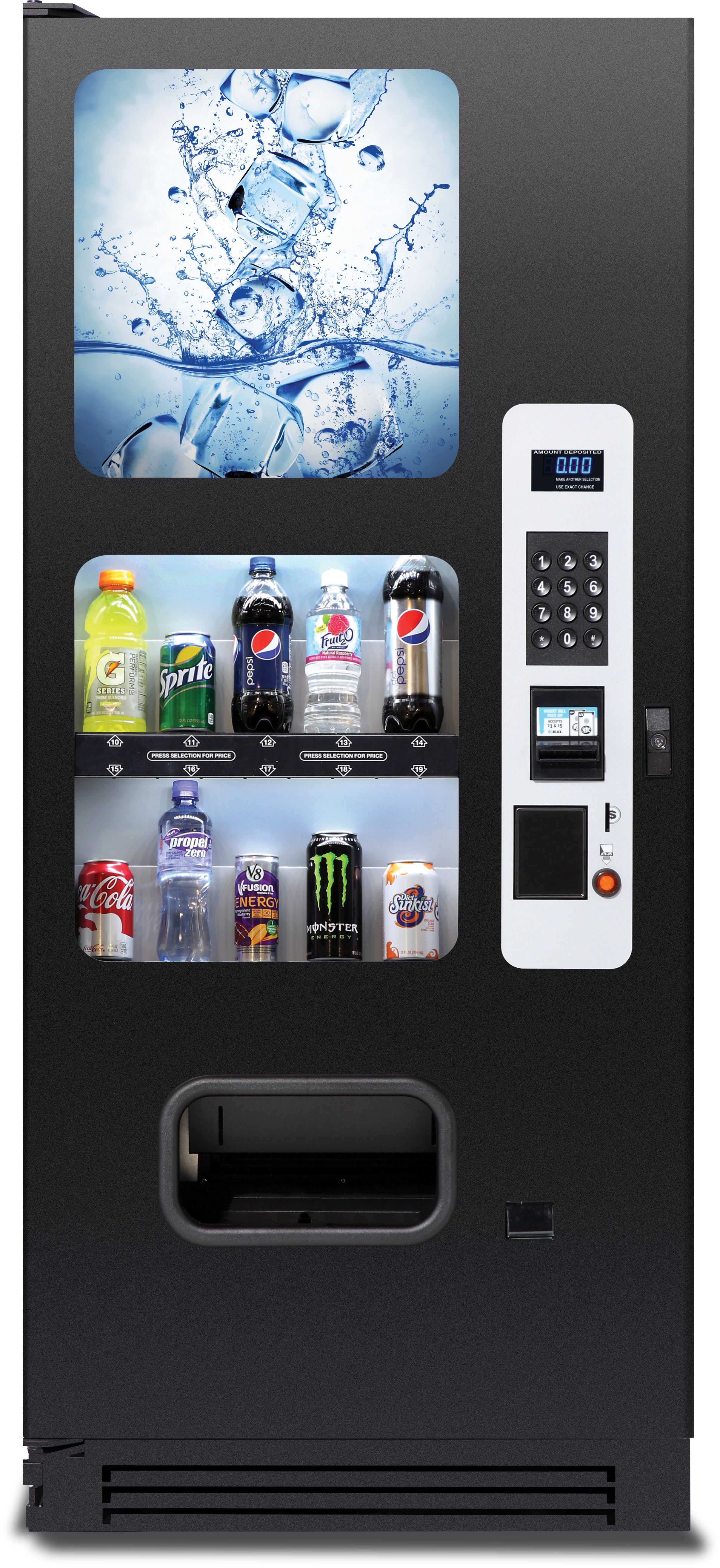

View NowBest Sellers

Get all of your favorite refreshments in one place with a snack and drink combo vending machines, complete with convenient card readers! Chips, candy, pastries, gum and mints, soda, juices, bottled water and even dairy products can be made available through combo vending machines. Our snack and drink combo vending machines feature various selections of snacks and beverage options, along with optional credit card reader capabilities. Additionally, these dual vending machines include a chilled option for the snack side, which prevents your chocolate candies from melting. The drink side of this combination drink and snack vending machine has the capability to dispense canned and bottled beverages, up to 24 ounces. These features, and many more, make it a complete snack and beverage vending machine for your customers.

Our combination drink and snack vending machines are built with two separate temperature zones in order to ensure the optimal temperature in your vending machine. This keeps your drink selections remain icy cold while your cookies and chips remain at a normal temperature.

Interested? Get in touch with us today to find out about our many affordable vending machine financing options.